By Laura Bécognée

When we think of industry, we often imagine giant factories, million-euro machines, and long production chains that seem completely out of reach for small businesses or individual innovators. But what if we could change that? What if tools once reserved for large corporations became accessible to makers, startups, and local communities? One of the best examples of the revolution described above is plastic injection molding.

What is Plastic Injection Molding?

Plastic injection is a process wherein plastic pellets are heated until they become viscous, then injected into a mold where they cool and harden. Once ejected, you get a finished plastic part—repeatable, precise, and strong. Unlike 3D printing, which builds parts layer by layer, injection molding fills a mold in one continuous push, to produce dense, durable pieces at much higher speed.

- 3D printing: 50–100 microns precision, a few parts per day, accessible machines (€200–€1,000).

- Plastic injection: 100–500 microns precision, hundreds of parts per day, traditionally expensive machines (€500–€40,000).

In short: 3D printing is great for prototyping. Injection molding is unbeatable when you need volume, strength, and repeatability.

Some examples

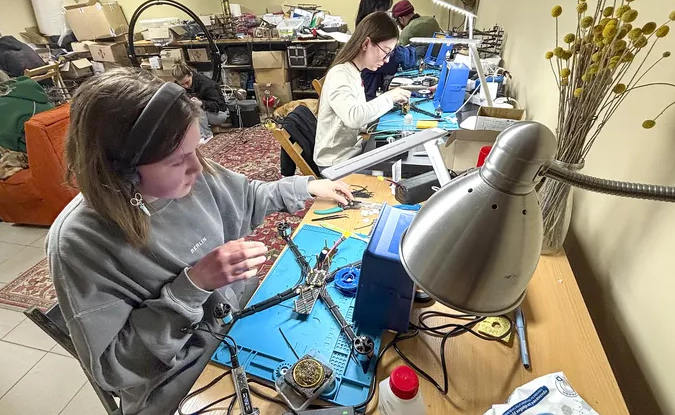

Here is a good example of a part that benefits greatly from plastic injection molding: a drone propeller with a sleek, aerodynamic profile and an ultra-smooth surface finish. The blades below are typically molded from reinforced nylon or polycarbonate – materials that flow precisely into the mold to create thin, balanced geometries with minimal surface and deep defects.

Attempts to produce this same part by 3D printing would introduce micro-imperfections, layer lines, and potential warping, all of which compromise thrust performance, making it prone to breakage and increased levels of vibration.

Here is another good example of a part that is better made with plastic injection than with 3D printing: a screwdriver composed of two different plastics — polypropylene for the core and TPU for the grip around a metal part. Both plastics are molded directly around the metal shaft, ensuring a strong bond. This process guarantees the sturdiness of a tool that must withstand significant pressure and prevent future corrosion. Producing it with 3D printing would not only take much longer, but it would also fail to provide the same level of mechanical strength.

Why does almost nobody speak about it in the maker space ?

Since its invention in 1872, plastic injection molding has fueled mass industrialization. But mass industry quickly locked the process behind huge machines and high entry costs, creating a system designed to exclude smaller players. What could have been a democratic tool for production was deliberately shaped into a fortress of mass manufacturing—leaving powerful capabilities inaccessible just when we need them most : small businesses, creators who need to scale to make a living, makers with a good idea to commercialize.

The way industrial production has evolved makes it unlivable for makers: the market has been shaped around large-scale players, not small workshops or individuals.

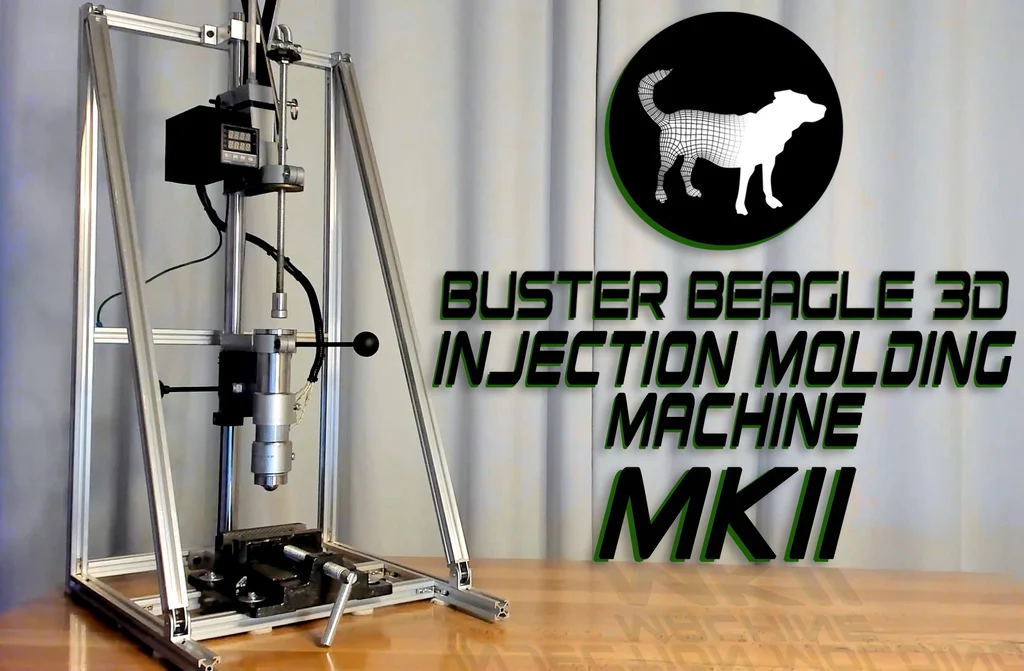

But it can change tomorrow, because instead of waiting for governments or large corporations to reindustrialize Europe, makers are creating their own tools. Affordable desktop-scale machines like the BB3D MK2 (~€500) already allow injection molding in a workshop or a small lab.

The advantages of this machine are clear:

- Open-source plans, Creative Commons licensing

- Easy to build, replicate, and improve

- Supported by active communities of builders and innovators

And once combined with 3D printing, the workflow becomes unbeatable: print molds cheaply, then inject for scale.

Why this matters for Ukraine

For Ukraine, accessible plastic injection molding could be a game-changer. Instead of relying on large factories that are costly to build and vulnerable to attack, communities could set up small, distributed manufacturing workshops. These workshops would allow more people to produce essential parts faster, cheaper, and with greater resilience.

Local makerspaces and innovators could experiment, adapt, and improve designs directly from the field, encouraging bottom‑up innovation rather than waiting for large industry to respond. This decentralization reduces dependency, strengthens local capacity, and turns creativity into a strategic asset.

A Roadmap

Small maker projects such as Precious Plastic helped raise awareness, but they do not provide a viable foundation for large-scale distributed manufacturing. Many of these machines are not reproducible or designed for performance. When we speak about resilience and industrial sovereignty, the focus must be on machines built to last and to evolve.

The more serious solutions today are:

- Small Asian machines available on AliExpress and similar platforms: affordable, immediately accessible, good enough for small series but with limitations in reliability and safety, not to mention the availability of spare parts in case of failure.

- Projects such as BB3D: a thoughtful open-source design, aimed at performance and scalability, which can be replicated and improved by maker communities.

To support this path, there are some essential software and networks. Fusion 360 remains the most popular among makers thanks to accessible licenses and numerous tutorials, while FreeCAD offers a flexible open-source alternative. Online communities like Hackaday.io, Reddit (r/hobbycnc), or Fablab Network Europe are, as with 3D printing, key partners. Finally, legal and safety aspects must not be neglected: high temperatures and pressures require strict safety standards around the machines, and intellectual property and norms for critical parts must always be integrated from the beginning.

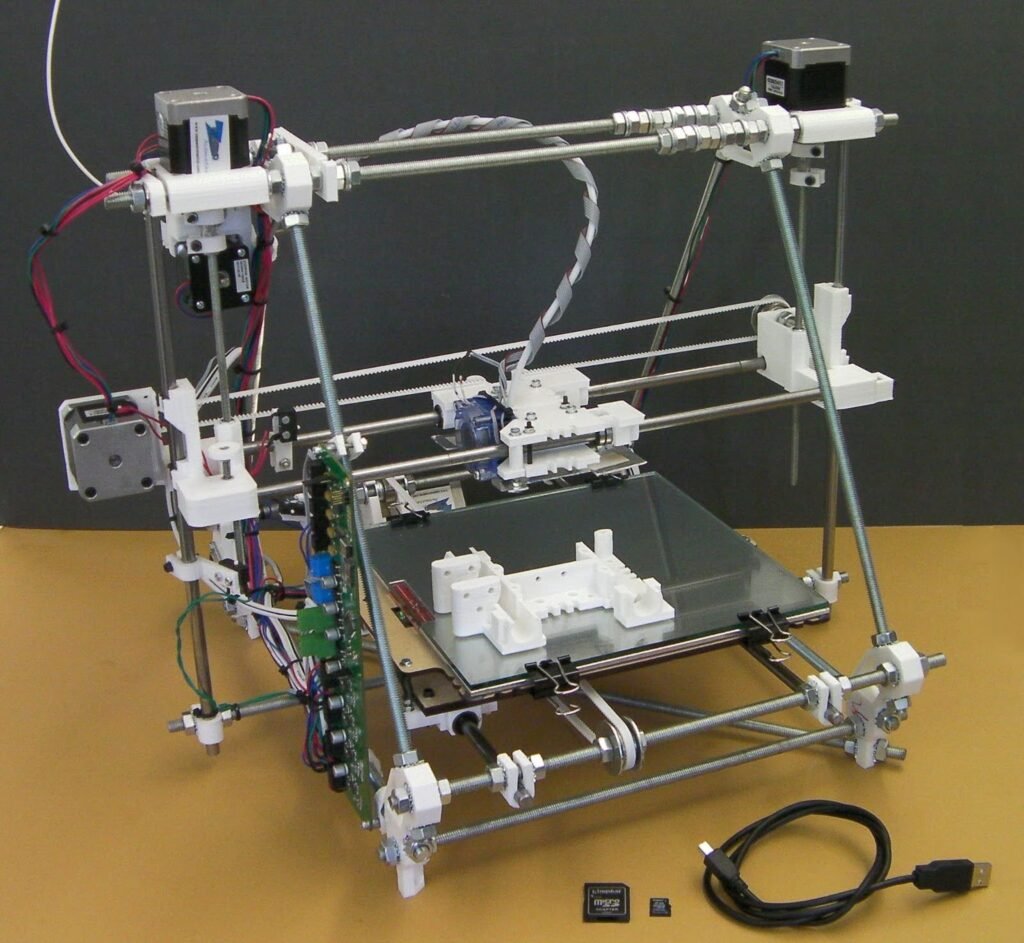

Today, very few makerspaces already have plastic injection molding. But a fablab that wants to prepare can aim for this objective by investing in a 5-axis CNC or by partnering with a workshop to create the machine parts. The real revolution will come when collectives start to build their own open-source injection machines, just as they once did with 3D printers or laser cutters before the market grew into today’s turnkey machines.

3D printing started humble, long before becoming the sophisticated machines we know today

The Bigger Picture

This is about more than just plastics or manufacturing. It’s about sovereignty through innovation and local development. By reclaiming access to industrial processes, we can reduce dependency on global supply chains, cut through bureaucracy, and empower local resilience.

Plastic injection is just the beginning. Other processes—metal casting, textiles, electronics—can follow the same path. The goal is not nostalgia for old industries, but a forward-looking productive rebellion: rewriting the rules of manufacturing to make it open, agile, and local.

This is not the end of the story.

It’s the beginning of a new one.

ABOUT DTU: DEFENSE TECH FOR UKRAINE

DTU is a volunteer-run nonprofit with well over 300 engineers, developers, experienced operators, project managers, donors and more working to accelerate the development and spread of critical technological tools to Ukraine’s heroic defenders. If you’d like to help in some way, whether by volunteering your skills or by donating financially, we’d love to hear from you via our site: https://defensetechforukraine.org

AUTHOR BIO:

Laura Bécognée is the founder of Ours Agile and a member of Defense Tech for Ukraine and European Action for Ukraine. An entrepreneurial maker with over ten years of experience, she focuses on local manufacturing, rapid prototyping, and open hardware. Her work combines technical innovation with civic engagement, helping to build resilient production networks that support Ukraine and strengthen European sovereignty